Our Products

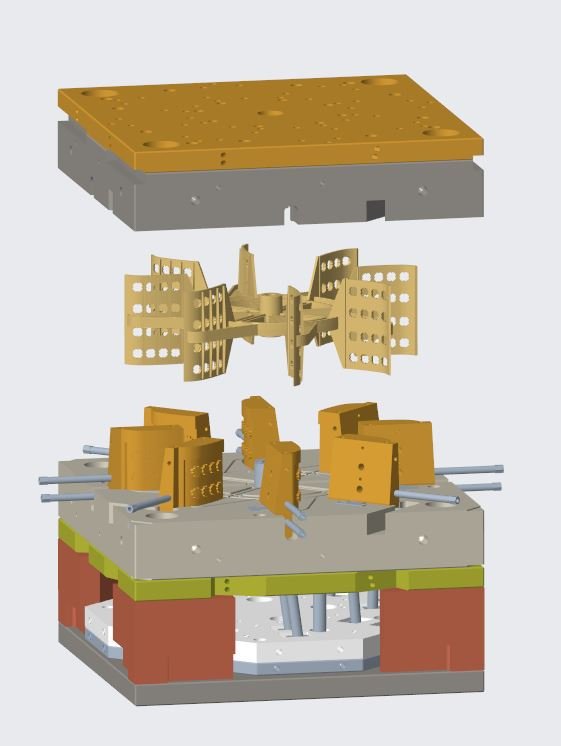

Injection Moulding Dies

We engineer precision moulds for the mass production of plastic components. Our focus is on creating tools that ensure flawless part quality, high productivity, and long-term reliability.

Description: We design and build multi-cavity, family, and single-cavity moulds for thermoplastics and thermosets. Our process emphasizes optimal gating and runner systems, efficient cooling channel design, and superior surface finishes to meet the most stringent specifications.

Key Features:

Designed for high-volume production cycles.

Manufactured from premium-grade hardened steels for longevity.

Capable of producing complex geometries with tight tolerances.

Options for hot runner systems available.

Applications: Automotive components, consumer goods, electronic housings, medical device parts, caps and closures, and technical components.

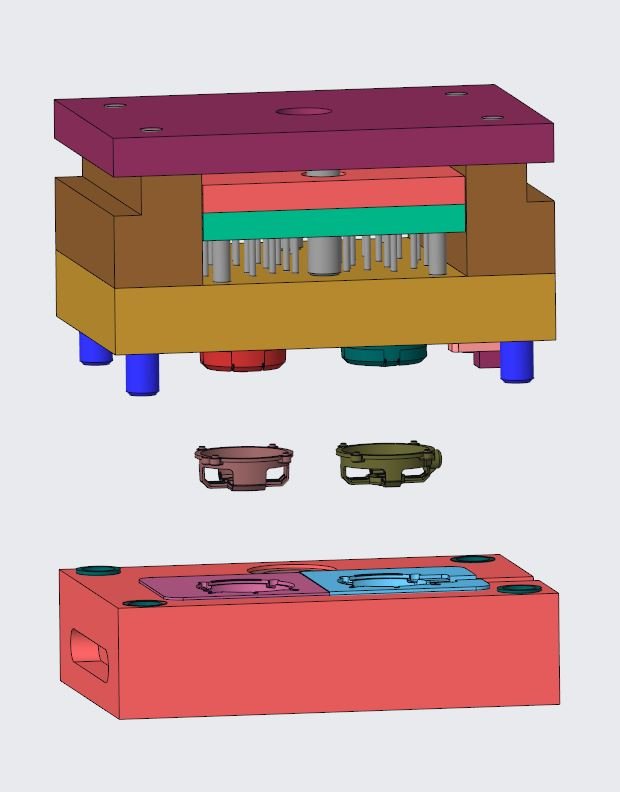

Press Tools

We manufacture high-duty press tools for metal forming and stamping operations. Our tools are built to withstand high-impact forces and deliver consistent accuracy through thousands of cycles.

Description: We fabricate a range of press tools including blanking, piercing, bending, forming, and progressive dies. Our expertise lies in creating robust tools with precise alignment and minimal maintenance requirements.

Key Features:

Designed for high-speed stamping presses.

Exceptional durability to minimize downtime.

Precision-ground components for perfect alignment and part consistency.

Applications: Electrical components, automotive brackets, metal housings, appliance parts, and stamped metal assemblies.

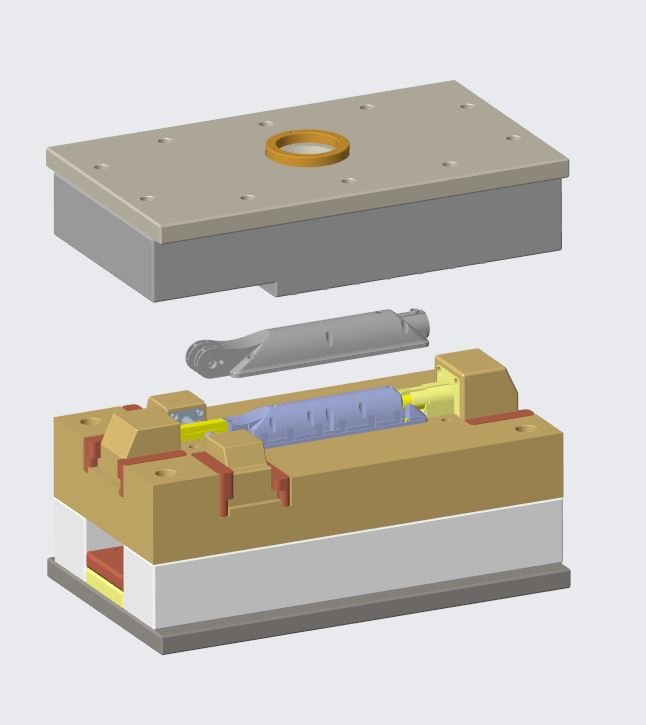

Die Casting Dies

We fabricate durable and efficient dies for high-pressure die casting of non-ferrous metals. Our dies are engineered to manage extreme thermal stresses and produce dimensionally stable, high-integrity castings.

Description: We build dies for zinc, aluminum, and magnesium alloys. Our design process focuses on thermal management through optimized cooling lines, venting for air escape, and the use of heat-resistant steels to combat erosion and wear.

Key Features:

Engineered for thermal fatigue resistance.

High-quality surface finishes for superior casting quality.

Durable construction to extend die life under extreme conditions.

Applications: Automotive parts, hardware fittings, industrial components, and consumer durable goods.

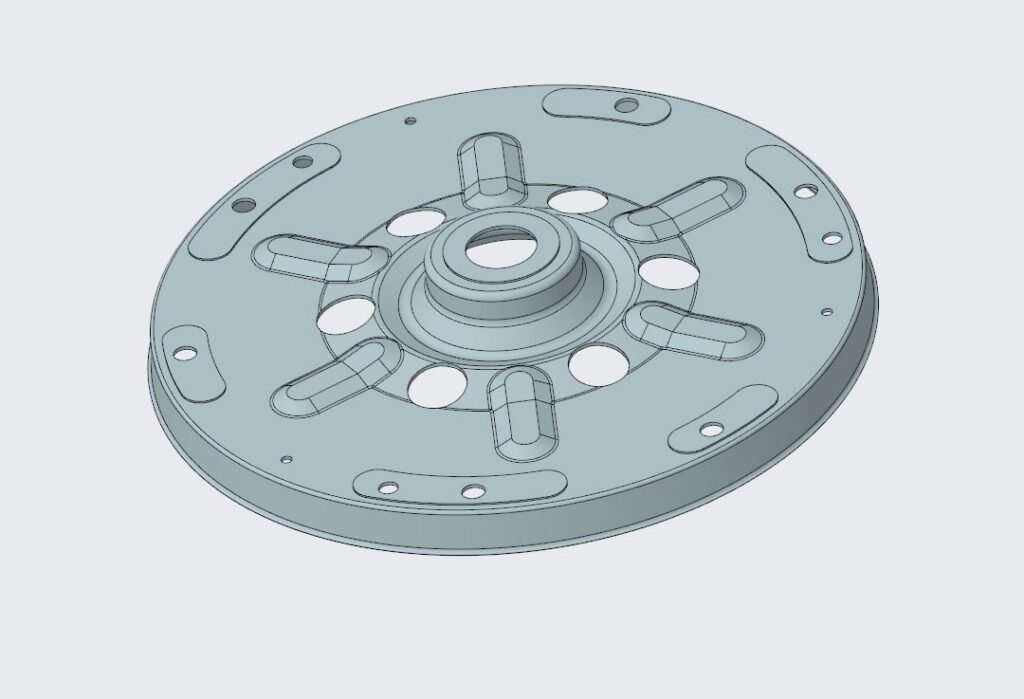

Custom Die & Tool Design

When standard solutions don’t apply, our innovation takes center stage. We specialize in designing and building fully custom-designed dies and specialized tools for unique applications and prototype development.

Description: We collaborate with you to engineer solutions for specific production needs, whether it’s a specialized fixture, a jig for a unique assembly process, or a tool for composite materials or prototyping.

Key Features:

Collaborative Engineering: We partner with you from concept to completion.

Bespoke Solutions: No project is too unique for our team to tackle.

End-to-End Service: Full in-house design, machining, and testing.

Applications: Prototype tools, specialized fixtures, jigs, tools for composite materials, and bespoke solutions for unique manufacturing challenges.